- Plaque Builder

-

Bronze & Aluminium

- Bronze & Aluminium Monument Gallery

- Steps To Order A Cast Plaque

- Plaque Basics and Options

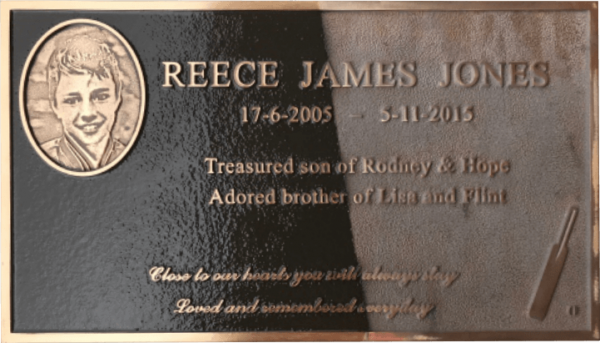

- Standard Memorial Plaques

- Book Plaques

- Ashes and Niche Plaques

- Side Design Plaques

- Design and Theme Plaques

- Commemorative Plaques

- Aluminium Plaques

- Borders Library

- Colours

- Bronzelife

- Plaque Mounting Options

- Plaque Bases and Displays

- Plaque Care and Maintenance

- Stone

- Guides

- About Us

- Contact Us

Frequently Asked Questions

FAQs

- Discuss with family, friends, neighbours and workmates.

Where possible, prior to visiting our office, talk to those closest to your loved one. Explore their interests and how they impacted their community, family and friends.

You might identify some themes to assist in selecting the words, emblems, symbols and styles to commemorate your loved one. Note these thoughts down and bring to your DP Jones & Co appointment. - View plaques at the place of interment

Plaque options may be limited by Cemetery guidelines so it's worth visiting the place of interment firstly, if time allows.

Speak to the Cemetery Trust team to understand their process and any limitations. Equally, the DPJones & Co team can assist with this.

Technology has expanded the potential design options of plaques tremendously and we can assist with the most straightforward to most complex designs.

No matter whether it's a few significant words to an extensive design involving border designs, photos, font styles, logos, etc, we can assist. Please jot down your ideas and come talk to us. - Check out our design guides on the DPJones & Co website

Please see our FAQ question "I’m looking to order a plaque and want it to stand out. What can I do?" (See below, it should be the next FAQ) for more detailed plaque design tips

Our full list of guides can be found here - Decide on your wording

When you feel ready, try drafting some plaque wording.

Find a quiet time to draft some words and let them sit for a while. For some, this can be a cathartic process. It may take some time and a few drafts for the words to come together the way you like and that's ok.

Our staff are very experienced at working with people to assist in this process. - Come and see us.

Please ask as many questions as you like at your appointment.

Bronze plaque personalisation is almost limitless these days so please let us know of any special requests.

Every plaque by its nature is unique and your options to personalise are almost limitless these days.

The intended location and size of the plaque probably places the most restrictions on what's possible.

PLEASE NOTE: Some Cemetery Trusts have rules governing the memorial size and design options allowed for certain cemetery sections. This may reduce or remove some design elements but there are still plenty of options to personalise your bronze plaque.

Once location is settled, choose the size and shape required.

Here's where the creativity can kick in. Start exploring the words and important information you wish to include.

Then consider:

Border style | Background texture | Background colour | Significant emblems and logos | Religious symbols | Ceramic photos

Next level design may include full themed backgrounds and borders (camping, sunset landscape, treescape, etc).

Most design features are automatically flat relief but can then be taken further with 3D elements.

For the latest in features and detailed design finish, BronzeLife may be considered to allow personal photos to be forever captured in bronze as background or a feature photo.

Take your time, consider what's important and the moments you'd like to preserve. Talk to DP Jones & Co staff for any assistance and carefully review the proposed Layout provided by DP Jones & Co before giving final approval.

All military badges require written permission from The Office of Australian War Graves to use. Permission must be sighted by DP Jones & Co before production can commence. It's the client's responsibility to obtain this permission.

Additionally, some logos and characters from TV shows, literature etc may require permission from the owner of these designs to use.

Please contact us if you require any assistance.

Flat Relief are 2 dimensional designs, images and text that are created with clean, smooth edges and a flat face, ideal for bronze manufacturing. Being computer generated at the first stage of production, they are easily re-sized and suitable for most plaque sizes and shapes.

Bas Relief is effectively 3D design which requires more handcrafting in the traditional Foundry production process. The final bronze image is raised from the plaque face and provides more depth and contours to the design.

This method can place limits on the types of designs and plaque sizes available for Bas Relief design features. Please feel free to discuss with DP Jones & Co staff at any time, we'll always try to find a solution.

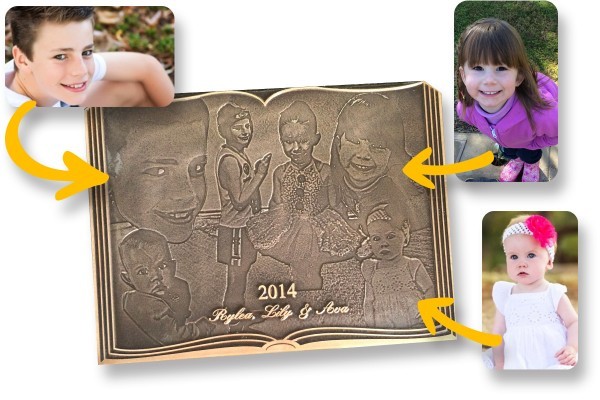

BronzeLife is a technique where DP Jones & Co reproduce your favourite photo(s) in bronze, beautifully capturing those memories forever.

We can work with one or a number of photos to create a wonderful Life collage as a plaque background or section.

We can also reproduce a single photo in bronze to be added as a detachable plate on a base plaque.

See here for more

There are several options available to attach your plaque and will vary depending on the planned location and base material (ie. on a wall, cement block, gate, etc). At time of ordering, you can select from:

- Lugs

- Brackets / Springs

- Pre-Drilled Corner Holes

- Flat Back

See here for more information

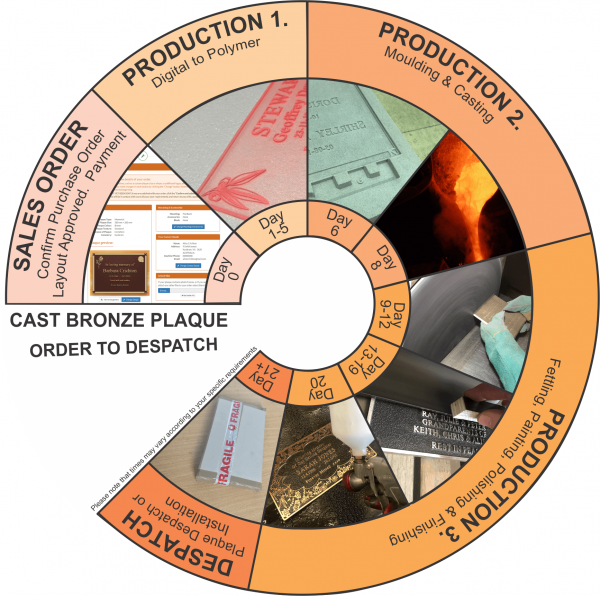

At DP Jones & Co we aim for an industry leading "confirmed order to manufacture" turnaround time of approx. 20 business days upon confirmation of a standard order.

Please note individual manufacture times may vary, particularly leading into Christmas and Easter periods. Contact us any time to query delivery progress

** Note, the handcrafted, personal nature of each cast bronze plaque means that timings are given as indicative only, no guarantees are provided.

Perhaps. Minor changes are sometimes possible even when a plaque has been cast and finished. One or two letters or numbers may be alterable with some careful work and this should not upset the overall look and plaque finish. Extra cost for this service would be incurred.

Usually, alterations larger than this aren't possible and a new plaque will be required at further cost.

It highlights how important the Layout approval stage is! Double check dates and name spellings.

DP Jones plaques are coated at final stage of production with multiple layers of an industrial strength, protective clear coating and then baked dry. This will provide many years of the rich, lustrous, beautiful finish that Bronze plaques are best known for.

In normal conditions, a regular dusting with a soft cloth should be all that's required.

We provide further details on plaque cleaning and the impact of natural weathering in our Bronze Plaque Care and Maintenance section

Yes, even Bronze Plaques can be impacted by a number of natural and local conditions over time.

Sunlight, extreme heat, water (chlorine, bore), chemical sprays (weed killer, industrial cleaners), salt, sand and wind can all cause weathering.

The plaque's protective coating will deteriorate over the years the more it's exposed to these elements. The deterioration allows moisture and air to come into contact with the bronze surface and oxidation to occur.

Oxidation causes the plaque to return to its natural bronze state and the external finish will patina, acquiring a greenish hue.

This natural finish is endearing to some and the plaque life is not compromised.

However, if it's time for a refresh, a professional reconditioning should be considered to restore its original finish.

DP Jones can assist. See here for more information on plaque maintenance and weathering.

,

Yes. Most plaques can be reconditioned back to their original, lustrous state.

For full steps, please see our Plaque Reconditioning section

This usually can be completed at a fraction of the cost of a full replacement plaque.